The concept of a Digital Twin has emerged as a game-changer in the realm of technology, blending the physical and digital worlds seamlessly. As industries continue to innovate, the adoption of digital twins is accelerating, revolutionizing processes and creating smarter systems. But what exactly is a digital twin, and how is it transforming industries?

What is a Digital Twin?

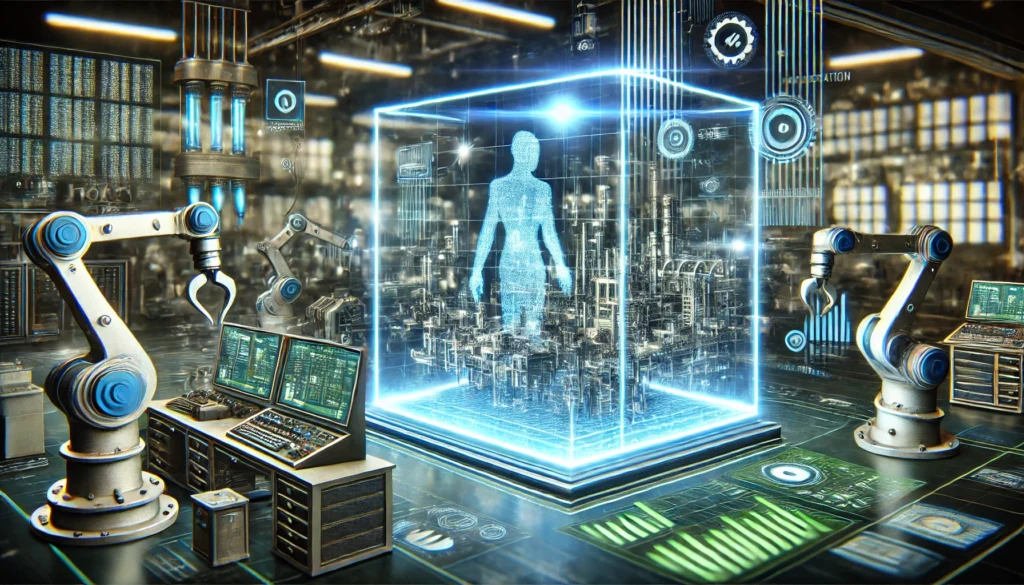

A Digital Twin is a virtual replica of a physical object, system, or process. It uses real-time data, simulations, and machine learning to mirror the behavior and attributes of its physical counterpart. This digital representation enables users to monitor, analyze, and optimize performance without directly interacting with the physical entity.

The concept extends beyond just replicating; it involves continuous updates and feedback loops, allowing for predictive insights and proactive decision-making.

How Does It Work?

The digital twin operates through three main components:

- Physical Object or Process: The real-world entity to be mirrored.

- Digital Replica: The virtual model that mimics the physical counterpart.

- Data Connection: Real-time sensors and IoT devices that feed data into the digital twin, ensuring accuracy and synchronicity.

For example, in manufacturing, a digital twin of a production line might gather data from sensors installed on machines. This data feeds into the virtual model, allowing engineers to predict maintenance needs, optimize workflows, and avoid downtime.

Applications of Digital Twin Technology

Digital twins are transforming a wide range of industries:

1. Manufacturing

- Monitoring equipment in real-time.

- Predictive maintenance to reduce downtime.

- Optimizing production processes.

2. Healthcare

- Creating digital models of patients for personalized medicine.

- Simulating surgeries and treatment plans.

- Enhancing medical device performance.

3. Smart Cities

- Urban planning through virtual city models.

- Managing utilities and traffic systems efficiently.

- Predicting infrastructure failures.

4. Automotive and Aerospace

- Designing and testing vehicles in a virtual environment.

- Simulating flight paths and engine performance.

- Enhancing safety and efficiency in transportation.

5. Energy

- Optimizing wind turbines and solar farms.

- Monitoring power grids in real-time.

- Enhancing energy efficiency and reducing costs.

Benefits of Digital Twin Technology

- Enhanced Decision-Making: Real-time data analysis allows for smarter and quicker decisions.

- Cost Reduction: By simulating scenarios, businesses can prevent failures and optimize operations, saving resources.

- Improved Efficiency: Processes can be streamlined based on insights from the digital twin.

- Predictive Capabilities: Foreseeing potential issues before they occur ensures smoother operations.

- Innovation and Testing: Virtual environments allow for the safe testing of new designs or processes.

Challenges and Future Prospects

While digital twin technology offers immense potential, it does face challenges such as:

- Data Security: The real-time exchange of data raises concerns about cybersecurity.

- Complexity: Creating accurate and comprehensive models requires significant expertise and investment.

- Integration: Ensuring seamless communication between physical and digital systems can be challenging.

Despite these hurdles, the future of digital twins looks promising. As AI, IoT, and machine learning evolve, the accuracy and utility of digital twins will only improve, paving the way for smarter, more interconnected systems.

Conclusion

The Digital Twin is not just a technological trend; it’s a paradigm shift that’s reshaping industries. By enabling better monitoring, predictive insights, and innovative solutions, digital twins are at the forefront of the digital transformation wave. As organizations continue to adopt this technology, the boundary between the physical and digital worlds will blur further, unlocking unprecedented possibilities.

Are you ready to embrace the future with digital twins?

FAQ: